YOU ARE OWED LOTS AND LOTS OF MONEY - READ ON AND FIND OUT

Welcome, Civilians, Retirees, Mare Islanders, Navy and Marine Corps, Army, Air Force, Government Workers and Other Victims To This Sad But Necessary Website.

You do not know it but you have been or are now being POISONED and your bodies are paying BIG for your work. You are not being told about this. Years of life are being secretly robbed from you and your family.

There are five reasons you should want to spend some time at this web site.

Reason 1:

The average American retiree lives about 15 years after retirement. This is to about age 70. The average life span of a U.S. Navy or other Navy affiliated shipyard retiree is about 16 months after retirement. This is about to age 56 so you are paying about 14 years of life that is secretly being robbed from you as a "reward" for your great job. This web site explains and demonstrates the causes of rapid ageing leading to premature shipyard retiree death. There is one more thing for you to consider. If you are a shipyard employee and your paycheck is inflated with overtime that you did not actually work then you should understand that no one gives away money for nothing. This fake overtime is a lot of "free" money and it has a name. This is "death wages" and you are being paid extra money in return for your shortened life and other health risks that you do not know about. If you are a U.S. Navy shipyard professional or clerical employee the U.S. Navy will not pay you death wages. This is true even if the circumstances and adverse health effects of your work are identical to those of another worker being paid death wages; and they probably are. Maybe you should talk to your Union about this. If your co-workers deserve death wages don't you? Your life is being shortened also. You deserve the death pay, retroactively, and with interest.

If you are or ever were a U.S. Government employee and you were ever secretly exposed to any amount of certain poisons they you should have been paid a special pay called "Hazardous Duty Pay" or HDP. This special pay has two benefits. The first is your bi-weekly paycheck is larger but the second, and massively greater benefit, is that when you are older and become sick or weak you are immediately elegible for Federal Employee Injury Benefits. When you are exposed to a known poison you have an absolute right to HDP just as you have a right to overtime pay when you work overtime. The reason you are not paid HDP is the people at your Federal Employer who count the money have made a conscious decision to rob you of this pay in order to avoid having to pay for the illnesses they have caused and that they know all about. If the danger you are experiencing is massive then they will, in many cases, soothe their burnt consciences by paying you overtime pay you did not earn. This is called the payment of death wages.

The reason your federal employer is so anxious to rob you of the Federal Injury Benefits is lots of money. The federal injury benefits program is run by the Federal Department of Labor (DOL). They are the ones who have the responsiblity. Prior to 1974 the DOL paid all claims but in that year the policy was changed so that the employer paid all claims. Prior to 1974 the DOL decided all claims. In 1974 it was decided that the employer should "administrate" all claims. This is called "Putting the Fox in Charge of the Chicken Coop" or if you are injured at work you lose. Mare Island used a number of techniques to "discourge" approved injury claims. Some of these may be used at your employer. These included reaching out to local doctors and giving them free trips to seminars so that the doctor would ask the claims office about the applicant before making a diagnosis. Needless to say the claims office would tell the doctor the employee was a faker and malingerer. Another tactic was to staff the claims office with people who got big bonuses for fewer approved claims. The number of dishonest tehcniques used by federal employers is endless but you can be sure on top of the heal is to make absolutely certain you never get paid Hazardous Duty Pay.

The one and only way to get the HDP you deserve is for your Union to file a grievance against your employer. The only problem with this is the empoyer will immediately attempt to generously bribe your Union officials to drop the grievance or to not prosecute it effectively. The amount of money involved is huge and so you should expect the employer to fight to win no matter what it may cost them or you. You may want to consider forming a group to hire a lawer to keep an eye on how things are going.

Reason 2:

There are some industrial processes that are so intensely poisonous they cannot be made safe but which must be done by human beings and that are absolutely necessary to the making and eminence of military ships, submarines. planes and other weapons. The worst of these will be found at shipyards and other maintenance bases. First and foremost among these is the electroplating of metal. Second is the welding and grinding of stainless steel. The metal plating process uses hideously poisonous chemicals that are released into the air all shipyard and other workers breathe. Welding and grinding of stainless steel releases the supremely powerful cancer causing chemical hexavalent chrome. The overall effect of all this release of various poisons is a highly increased rate of cancers, birth defects, lung diseases, sinus diseases, and many other permanent and severe adverse heath effects. All the various poisons combine and multiply causing a vastly increased health wrecking effect. Those people exposed to these chemicals who do not die quickly get their lives shortened. This life shortening usually becomes evident only when one reaches retirement age. My advice to those receiving death wages is save this extra money and don't buy toys and, vacations and custom homes with it. You will be needing this money when your health collapses. This will come sooner than you think. Everyone working now or who ever worked at such bases should be paid at least 100% retroactive hazardous duty pay with interest. Talk to your Union about this.

Reason 3:

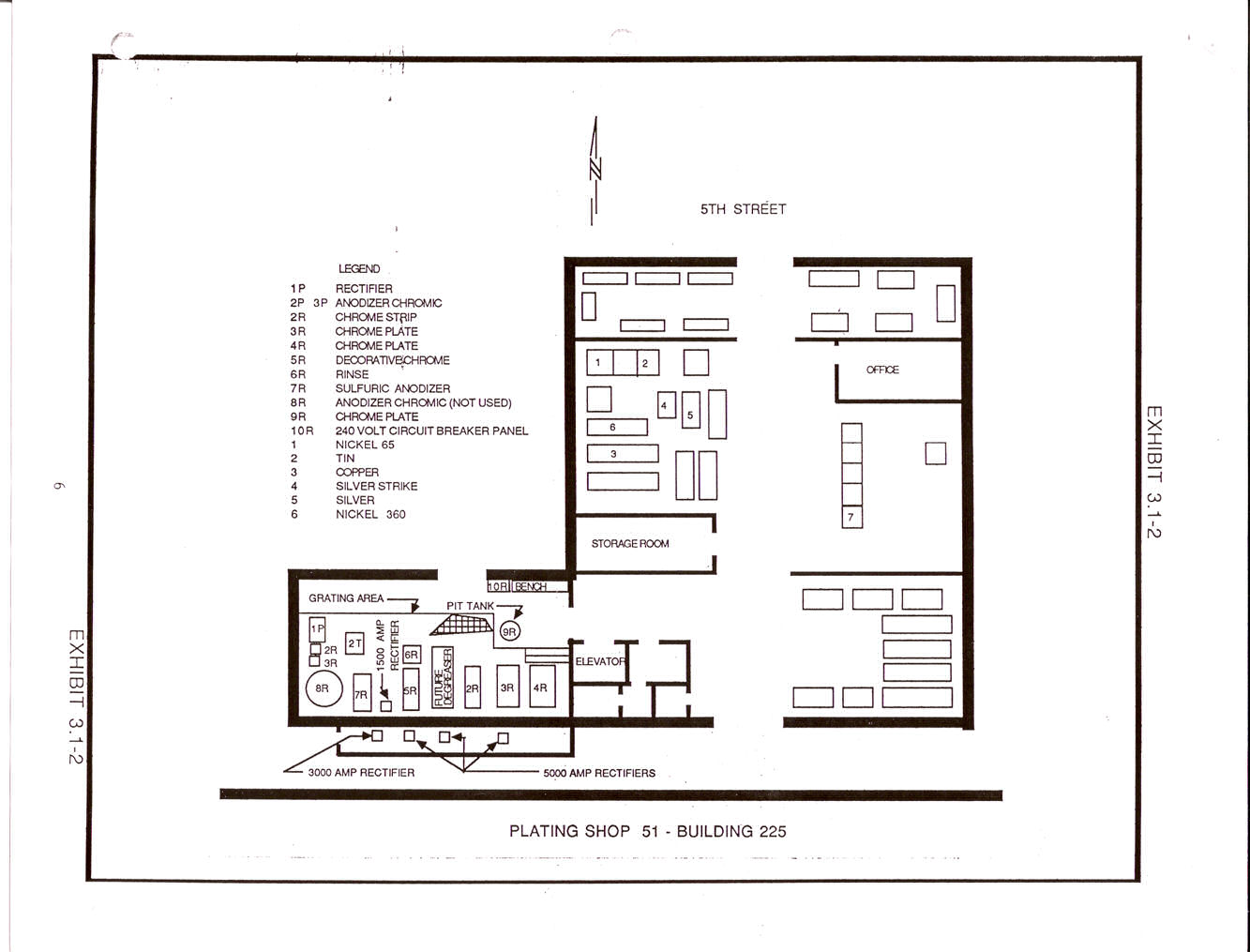

If the base you work at has a metal plating shop it is an invisible volcano of hugely harmful quantities of super toxic poisons you cannot fee, smell or taste. These poisons are robbing you of years of your life and making the end of your life more painful and difficult for you and your family. You cannot feel this process now, but you certainly will feel it. The reason for this is very simple. It is dust, normal dust. The pollution control devices installed on the outlet of air ventilation fans installed in the plating shops to protect the people who work in them have a huge defect. The pollution control devices are called "scrubbers". Their purpose is to remove the many billions of small particles of poisons that are released into the air by the metal plating processes. The scrubbers are continually self-washing and remove these poisons and keep themselves clean. These poison particles dissolve in water. Scrubbers are designed to remove particles that dissolve in water. Scrubbers are also super effective at removing normal particles of dust from the air. These do not dissolve in water, are not washed out of the scrubbers, build up and clog them in a short time. In any normal industrial environment where there are people, machines and activity a lot of dust is generated. The scrubbers make the plating shop ventilation system to be a huge vacuum cleaner whose "bag" is never emptied. Just like any normal vacuum cleaner, when the scrubbers quickly become full of dirt they clog and don't filter the air fill of poison particles from the metal plating processes and release it into the air for you to breathe. A metal plating shop absolutely must have two air filtration systems to be safe for everyone. It needs a complete air filtration system to clean the air coming into the shop to remove the normal dirt from it to keep the scrubbers working as they were designed to do. If this first air filtration system is not installed the result is the scrubbers quickly fill up with dirt and then they don't work. The U.S. Navy plating shops, none of them, have this absolutely necessary front air filtration system. The result is shortened lives and health misery at the end of life. All you need to do is to go and take a good look at the plating shop at your base. If your shop does not have a large building with an "input" air filtration system installed in it then you need to get your Union to file an emergency grievance to get you the long overdue hazardous duty pay and to get such a system installed fast.

Reason 4:

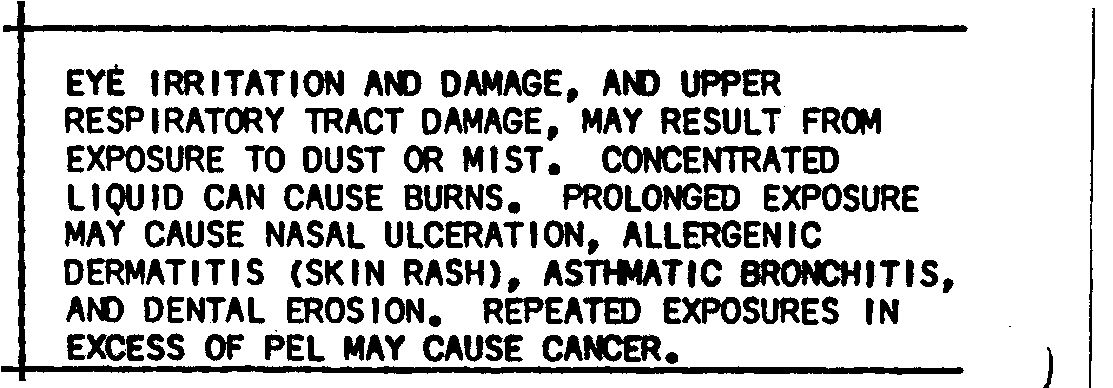

There is a very good reason you cannot smell, taste or feel the poisons that are robbing you of years of your life. Some of them are anesthetics. When you are exposed to them at first, and for a very short time you may smell a strange burnt sugar kind of smell. This is the deadly poison cyanide that was used in the Nazi Death Chambers at Auschwitz. The deadly poison Cyanide is a very common chemical that is necessary for many metal plating processes. It is used in extremely large quantities and large quantities of it are released to the air. You will only smell it for a short time because it is so incredibly deadly it kills the nerves in the nose. The amount of cyanide that will easily fit on the top of a large nail head will easily kill 100 people. When you are exposed to it, it stops your nose from being able to smell. The chemical "hexavalent chrome" (hex-chrome) is used inside plating shops for chrome plating, to clean metal and to corrosion-proof aluminum. It is a contact anesthetic. When you are exposed to it you cannot smell it. The effect of hex-chrome is insidious. When it gets into the body it is a super radical that has permanent effects upon the body and, even more importantly, it is a trans-generational genetic poison. It seeds your children with genetic damage that will cause birth defects in your grandchildren and following generations. It also causes lung cancer with a 20 year average delay period along with many other forms of cancer that are known to be super aggressive cancers. It turns the inside of your lungs into leather making it harder and harder for you to breathe. It causes heart disease. There is no known safe level of exposure to hex-chrome. If you are exposed to even tiny amounts of it, even infrequently, you should be paid huge amounts of hazardous duty pay that is retroactive and with interest.

Reason 5:

No one, including any medical doctor, can tell you what the symptoms are when you are poisoned with anything. The cruel fact is if you are poisoned you are going to find this out for yourself the hard way by living with it. The law forbids to expose human beings to known poisons to find out what these poisons do. The result of this is almost nothing is known about what poisons do to a human being. Every ting in the medical books is just guesses. The super poisonous chemicals used in metal plating shops were invented over 100 years ago. Since then crude safety measures to keep the workers inside the shops alive long enough have been invented. But no one every thought about what these poisons did to the people outside the shops. Another big problems is that when a human being is exposed to multiple poisons the poisons do not just add to each other, they multiply each other. If you are exposed to a group of five poisons released from a plating shop the effect in your body, if the total poison effect of each poison is 2 years of life cut from your life; the total effect of all five poisons is 2 x 2 x 2 x 2 x 2 = 32 years. Most plating shops will pollute the outside air with at least five lethal poisons if not more.

Reason 6:

If you think your supervisors or managers are going to protect you, warn you or inform you about the poisons you are being exposed to then think again. They are not your friends and cannot be your friends. Many supervisors and managers know exactly what is happening but they keep their mouths shut. The reason for this is money. Every government department has a slush fund called a "bonus fund" used to reward managers and supervisors every year. It is a very common policy for the cost of all occupational injuries in any department to be subtracted out of the bonus fund. Any manager or supervisor who does anything to risk even a penny being taken out of this fund is going to be hated by all the other managers and supervisors and he will not be promoted. If you believe anyone is going to protect you then you should think again. You deserve to be paid full retroactive hazardous duty pay with interest for all the years you have been poisoned. Go to your Union and demand they take action for you.

The Most Important Reason:

Any metal plating shop will emit a lot of different poisons but one of them, the most important one, Hex Chrome, is by far the worst. The reason for this is it poisons your grandchildren and their children and grandchildren. Basically, it ruins your family line by seeding your descendants with genetic defects that take a generation to be expressed. This happens by your being exposed to it; even tiny amounts of it. The reason for this is simple. Hex Chrome is what is called a "Trans Generational Genetic Poison" or TGGP. Hex Chrome causes a lot of different kinds of cancer. Cancer is a disease of the DNA and so it is a genetic disease. This cancer causing ability of Hex Chrome makes it a genetic poison. Hex Chrome is a super powerful cancer causing chemical. The thing about it that makes it Trans Generational is its uniquely tremendous and selective DNA destructive power. Most poisons that get into your body are neutralized by the liver and excreted through the urine. Hex Chrome is unique because the liver has no method to detect it or to process it. This means it must circulate in the body until it has been worn out by doing damage. Hex Chrome is the ultimate "free radical". Most, if not all, other "free radical" type chemicals that get into the body have an electrical charge of +1. This makes them easy for the body to neutralize. Hex Chrome has a incredible charge of +6. This means it can only be neutralized by something in the body that can only be damaged by such a large electrical charge and this is mostly the DNA in the reproductive system. To put it a simpler way, when animal skins are tanned and turned into leather it takes the process using natural ingredients like tree bark extracts 12 months to complete; when Hex Chrome is used to tan leather it takes 30 minutes to do the same job. When you are exposed to Hex Chrome you are undergoing the process of being turned into leather and leather cannot have children. Hex Chrome is painless because it is an anesthetic. Hex Chrome has been called a "de-natureant" for at least 100 years. This term means it removes what it touches from nature. This ought to tell you that the people who have been exposing you to it know exactly what it does to you. 100 years ago doctors used to use Hex Chrome to remove warts, but they give this practice up when the warts were soon replaced with an aggressive tumor that killed the patient. A lot of innocent people have been secretly exposed to this stuff and there are a lot of descendants who suffer because of inherited birth defects of all kinds caused by it. Don't you think enough is enough?

Why have you not been paid?

You have not been paid because the amount of money involved is so vast no one can afford to pay it. So the matter of Hex Chrome poising has been kept secret just like the effects of asbestos were kept secret. Imagine if all of the victims and affected descendants of over 100 years of deliberate Hex Chrome poisoning were to be awarded a fair and just award by a court of law? Do you imagine that anyone could possibly pay it? Hex Chrome is a scandal far worse that asbestos ever was but it is still a secret. Why is it a secret? No one has enough money to pay the costs of what they have done. If you worked at a Navy or other Government shipyard you depended upon the other employees who were hired to protect your health in the Occupational Health Department to warn and protect you; but they did not. The Government was very careful when it came to selecting the head managers of these departments. These managers had no consciences and cared only for their personal careers, promotions and yearly bonus payments. Just the "right" kind of people were selected. I believe they were all psychopaths. These "managers" made sure the people under their supervision kept their mouths shut or they would be punished. Anyone who dared to even speak of hex chrome poising was made subject to a cruel severe regime of work place harassment, intimidation and punishment designed to hurt them to shut them up. I know all about this because as Union President I handled such cases as they were prosecuted against innocent employees who only wanted to protect the other workers. Now it's your turn. You need to find layers who will do the WORK to get you paid what is owned to you because if you don't you will get nothing.

The Poisoning at Mare Island is NOT an isolated occurrence; it is Normal at all shipyards and all other metal plating shops everywhere.

The Mare Island Shipyard Metal Plating Shop and all other U.S. Navy and other U.S. Government Metal Plating Shops

Were Are The Factories of

Severely Shortened Worker Life

Childhood Autism, Family illness

Premature Death,

Birth Defects, Cancer, Lung Disease and Other Incurable Diseases.

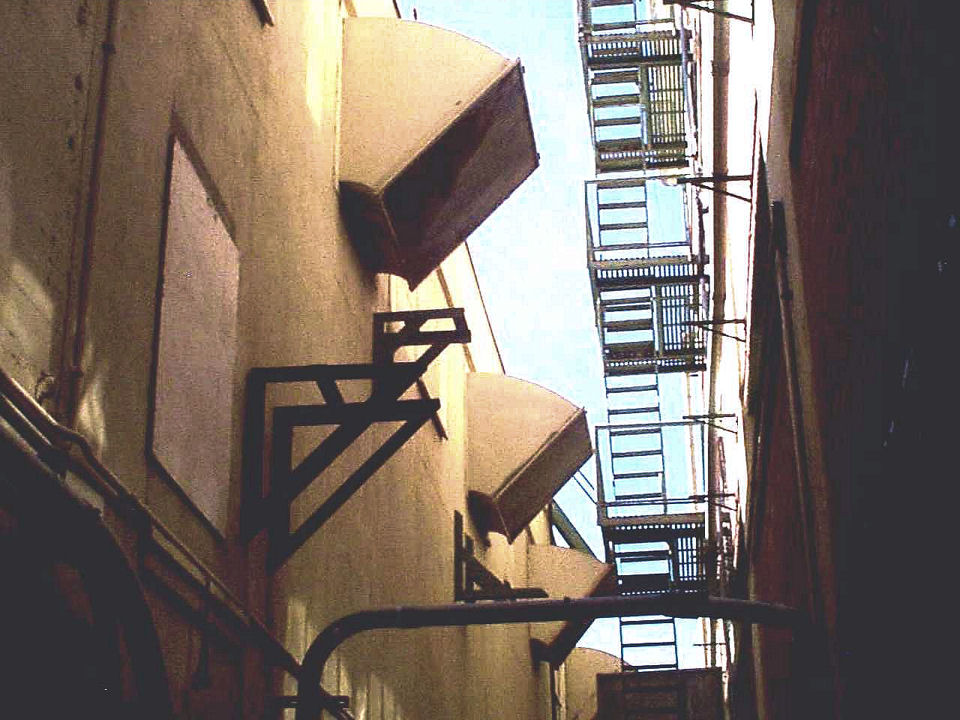

This is a picture of the Mare Island Shipyard metal plating shop as it is today. This building released vast quantities of highly toxic chemicals into the air. There are three reasons for this and they are strongly related to money (and lots of it), fear contempt, ignorance and Navy Prostitutes. Here they are:

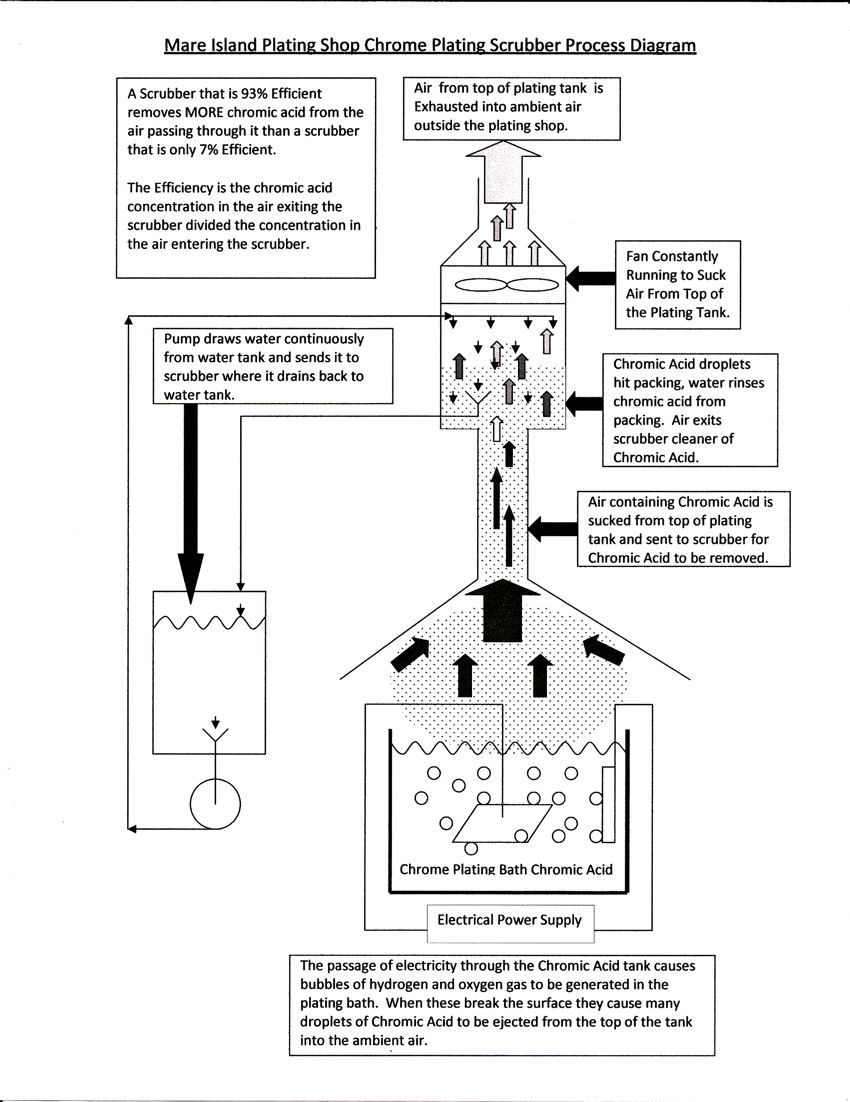

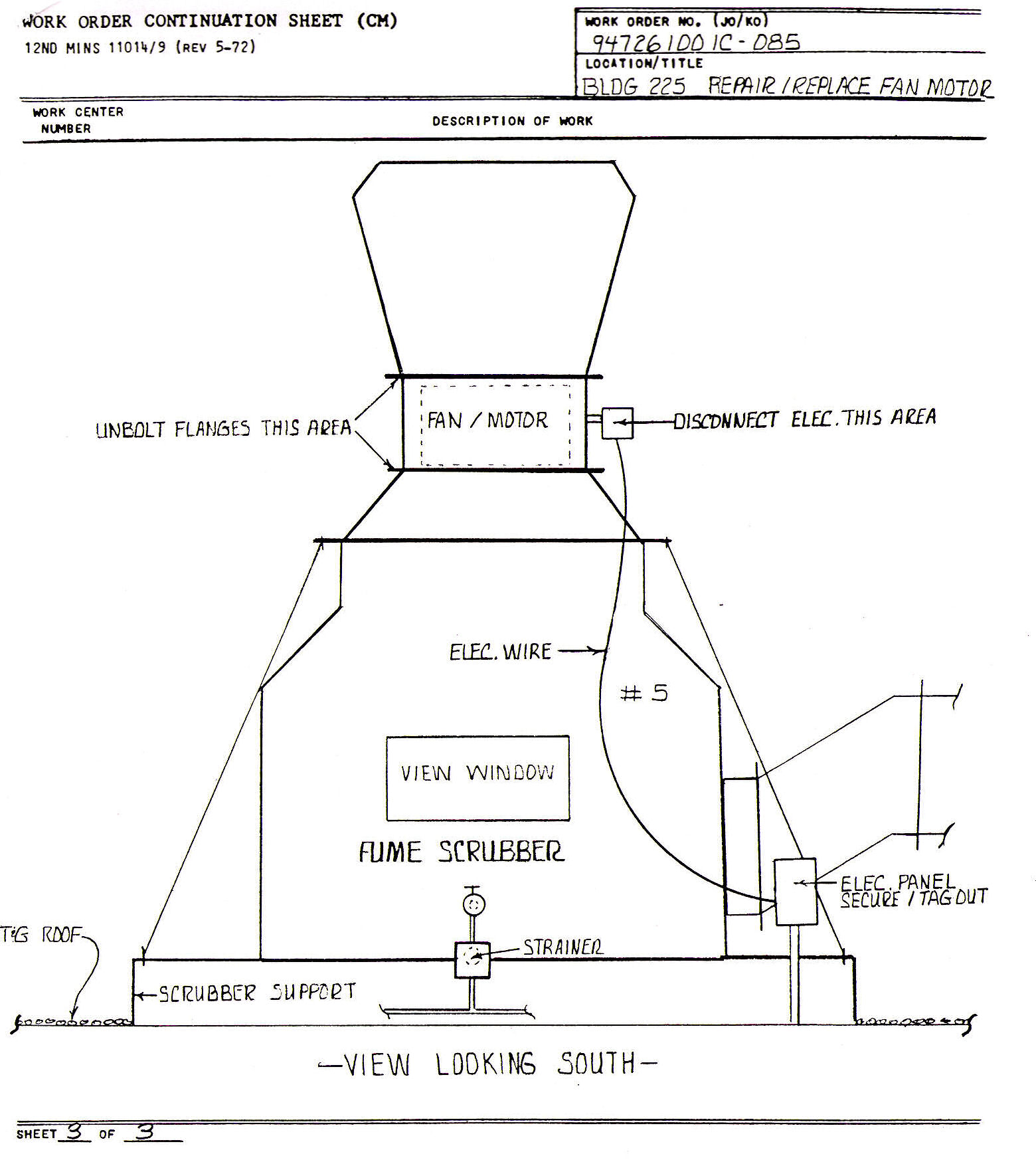

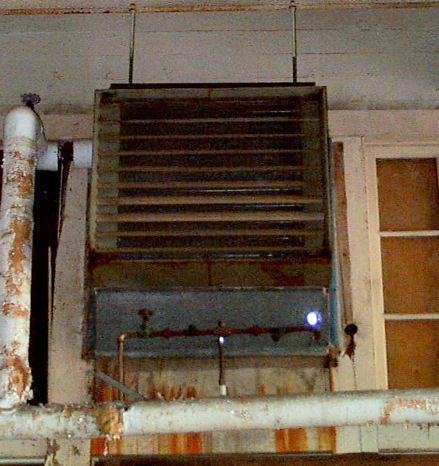

1. Money: You can see the air vents all around the top edge of the building. These vents were used to allow air to enter the building so that the safety system that sucked air from above the tanks full of toxic chemicals inside the building was removed from the air the workers in the shop would breathe. This air was then carried through vent pipes to air scrubbers on the building roof and then vented to the open atmosphere. The scrubbers are basically boxes full of pieces of plastic upon which water is sprayed. The droplets of poison pulled from above the poison tanks hit the plastic pieces and the flowing water rinses the poison off of the plastic pieces and carries the poison away. It's all quite simple but it is extremely expensive if it is done right. The water that leaves the scrubber becomes so contaminated with the poison it becomes federal and state hazardous waste. This means it can only be disposed of by specially trained people, with lots of paperwork, in 50 gallon drums that must be shipped by a special shipper to a specially designated repository. The cost is about $500.00 per gallon with all things considered. A typical scrubber will turn about 11,500 gallons of clean fresh water into hazardous waste a day and this costs about $5,750.000 per day. This is far too much money. It's just easier to not provide water to the scrubbers and to let the poisons be released into the atmosphere so everyone on the shipyard gets to breathe them at the cost of years of their lives.

2. Fear: The scrubbers are given absolutely no preventative maintenance. As you can see from the above picture the air inlets to the plating shop have no filters installed on them. Shipyard air is very dirty air. A shipyard is a hard core industrial place with many welders, grinding machines and other industrial processes that create a lot of dust and dirt that gets released into the air. The plating shop itself had 12 huge grinders in it that fed their dust to the scrubbers. If you look at any shipyard you will easily see most of the buildings contain numerous air outlet pipes and just about all of them are dumping something into the air. The plating shop sucks a lot of this air into itself. It's like a huge vacuum cleaner and the scrubbers are the dirt bags. Over time, and not a lot of it, this muck in the general shipyard air gets pulled into the plating shop. Then it gets captured in the scrubbers. When all this metal dirt, grinding dust and other industrial airborne waste combines in the scrubber with the poison chemicals from inside the shop it forms a very hard rock like deposit on the plastic pieces. Over time this deposit grows and welds the plastic pieces together and finally it blocks the scrubbers. When this happens the liquid poison droplets carried in the air condense in the scrubber and begin to flow back through the air pipes and drips back into the plating tanks. The plating tanks are full of very expensive supremely toxic chemicals. The chemicals are very expensive because they must be very pure to produce the high quality results the navy needs. The tank contents are very quickly ruined by this back flow of dirty water. This is when the plating shop has an emergency problem big enough to compel some scrubber maintenance. The reason this maintenance has been delayed is fear and fear for good reasons.

The problem with scrubber maintenance is human beings have to do it. Every worker on the shipyard knows the plating shop is a bad place and they are terrified of it. This is because they know the workers in the plating shop. They tend to be sick a lot and have a greenish color to their skin. Plating shop workers go to the shipyard clinic to complain where the factory doctors tell them to quit whining and get back to work. No one in his right mind wants to be like them. Everyone knows the scrubbers are packed full of every kind of poison there is. No one wants to work on them and I mean no one. I was never able to figure out how the shipyard ever got anyone to clean out a clogged scrubber. All I can think is they must have been given lots and lots of extra money in the form of performance awards or perhaps their paychecks were padded with a lot of overtime they never worked. It was just easier to let the scrubbers fill with rock meaning everyone on the shipyard got to breathe very strong poisons that shortened their lives without knowing it.

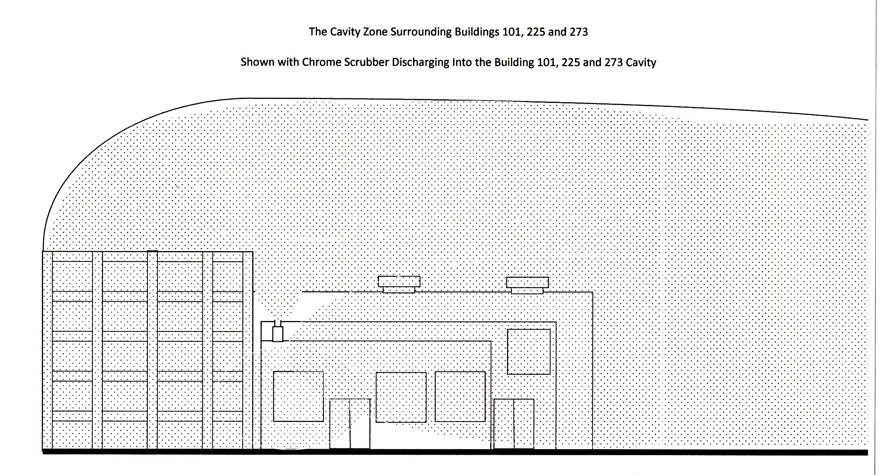

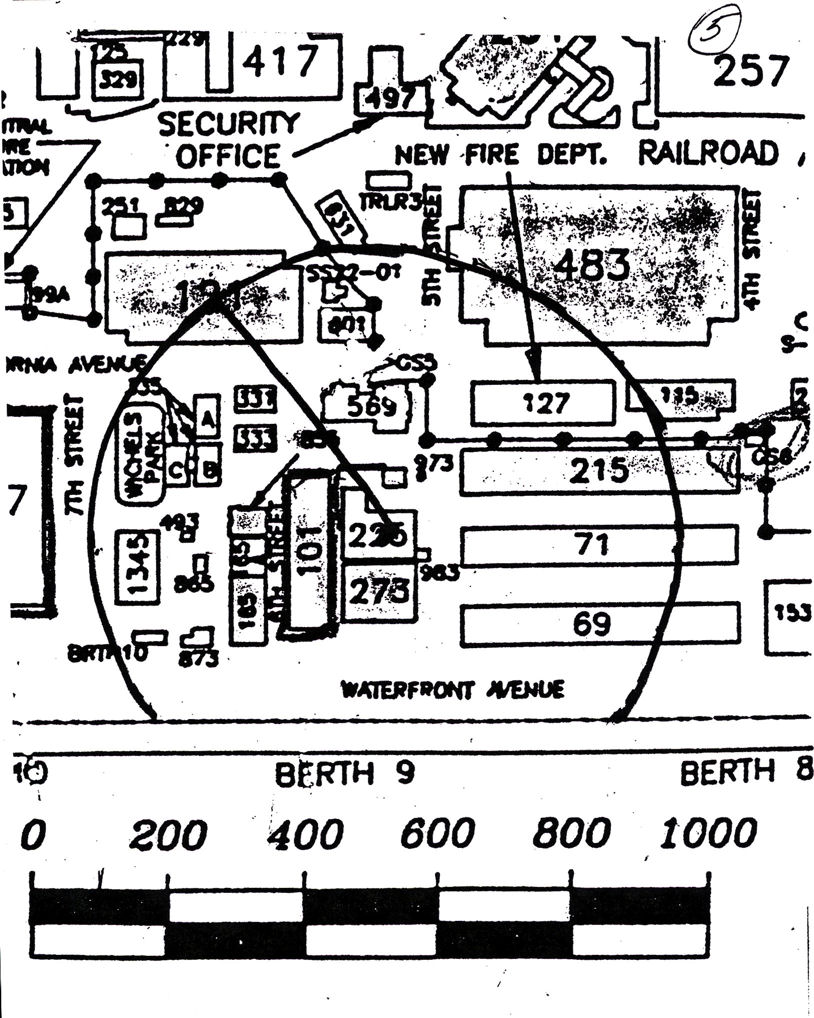

3. Contempt: The third reason is contempt. The navy has complete, absolute and total contempt for its civilian employees. The navy does not care it is slowly murdering them. This is demonstrated by the presence of the five story building behind the plating shop. It's just too close to the plating shop. Everything that was discharged out of the roof of the plating shop was discharged into the adjacent building. In actual cruel fact the plating shop was actually the main source of breathing air for the adjacent building. This building was the Nuclear Engineering Building. It was full of all kinds of engineers, secretaries, managers and other workers who are supposedly valuable. All of these unfortunate people were at Ground Zero for being poisoned. The way we know the Navy knew all about this is the fifth floor. If you look at the side of this building that faces the plating shop you will see the windows have all been bricked up. This work has been expertly done and concealed to make everything look as normal as possible from the outside. But if you can get into this building and go to the fifth floor the windows are still visible and they are all filled with bricks. These bricks kept victims from being poisoned enough to be taken to the hospital but not enough to prevent many of them from having 15 or more years erased from their lives.

4. Ignorance: It is medically forbidden to expose human beings to known poisons to find out what those poisons do to them. This means that for a lot of poisons used in industry almost nothing is known about what they do to human beings who work with or who are exposed to them. This may seem strange but it is the way things are. Most, if not all, of the extremely deadly chemicals used in the plating shop were invented long before the words "industrial hygiene" were invented back in the 1920's. They got invented, got used carelessly, people using them died young, and practices and procedures that allowed the chemicals to be used with people dying more slowly became adapted. There was no science involved in this process.

It is now well known that when a human being is exposed to multiple deadly chemicals at the same time the result is not that the poisonous effects add up. They actually multiply. There is no book of any kind that anyone can go to and find out just how incredibly toxic the mixture of deadly poisons discharged from the plating shop are. There is no way to find out what all that deadly stuff actually did to people except for them to be exposed to it and for them to have to endure the effects. There is no such thing as a poison "antidote". The antidote is a thing of fiction and movies; not for real life. Once a person has had his health broken or broken by being exposed to the deadly poisons discharged out of the plating shop he has to live with it until he dies and there is nothing any doctor can do to make it any better. There is no doctor who can advise him about what is coming next. The effects of the poisoning are going to unfold over time and nothing can be done to stop this.

The long and the short of the situation, even today, is very simple. This is no one can tell you what the toxic mix of deadly poisons being emitted from shipyard plating shops today is doing to people except for one thing. It is all bad. The effects can range from immediate lung cancer to having your heath collapse at the age of 56. What will happen to you is probably somewhere in-between but this is not certain. All anyone can know for sure is exposure to the air released from a shipyard metal plating shop does health damage and the longer you breathe it the more damage is done. Some people only need a little of it to be finished. Some need a lot. There's no way to tell. My advice is no matter how much you are paid if you work anywhere that has a plating shop find another job as fast as you can.

5. Navy Prostitutes: The navy has no problem finding and paying people who will lie for them. This is necessary in time of war to protect secrets. As Winston Churchill famously said, "During war truth must be surrounded by a bodyguard of lies". It's the same all the time at the Shipyards. The U.S. Navy must have new ships. Making new ships costs people their health. It is inherently unsafe. Human beings must make them. Shipyards are life-shortening places that people would not work at if they knew the cost to their health and life-span. Lies are necessary. It's as simple as that. The navy has no problem finding and training convincing liars to say comforting things to its workers. It has no problem constructing a fake phony "Industrial Health and Safety" department whose real job is to create false documents and to lie and manipulate to create the impression of safety in the complete absence of it.

The simple fact is the real situation is all explained by kitchens and bathrooms. The air that comes out of a kitchen smells good. It smells good because it's tiny bits of the food that are being cooked being carried through the air to your nose. Imagine what it would take to stop it. How much money would you need to spend to equip your kitchen with air fans and filters so that you would not smell what is cooking? The same goes for bathrooms. What goes on there gets to your nose and you know what it is. It's the same for a metal plating shop. The U.S. Navy will not spend the money it takes to make sure that tiny particles of the deadly chemicals used inside one do not escape into the outside air the workers breathe. It would cost too much. Instead it's easier to purchase technical prostitutes, hacks, dishonest managers and all the other psychopaths needed to fill the workforce with enough comforting lies to make sure the ships get built.

A typical Navy expert industrial hygienist prostitute will say: "It's a dose to response relationship. There is a dose of poison small enough so that there is no physical effect". They will say this under oath. And even though it is a lie they believe it because they are paid to believe it. They also know they will be severely punished if they do not say it. The fact is that it is now known that for some chemicals, and the most serious of these is the chemical used for chrome plating, there is absolutely no safe dose. There is no amount of this that you can be exposed to and still remain safe. This fact is published by the State of California itself. Yet the safety prostitutes hired by the navy repeat the same lie over and over again.

My advise is simple and it has two parts. First: Believe your nose. If your bathroom stinks then so does the plating shop. The only difference is that the smells coming out of your bathroom are not likely to ruin your health permanently. But the deadly chemicals coming out of the plating shop can turn off your nose so you have no warning even if that place is belching out a enough poison to cause you to lie dying of lung cancer in 3 years. Second: why not ask the shipyard commander for a guided tour of the plating shop? You might find his reply interesting. My guess is if you have the guts to do this he will make sure the next thing that happens to you is that you get fired on one trumped up pretext or another and what does this tell you about the deadliness of the metal plating shop?

Update 5/27/16: New Scientific research released early on March 26, 2016 and in July, 2015 have conclusively determined that Autism is a physical brain defect formed during pregnancy as a result of genetic damage. Autism is a genetic disease caused by genetic damage. I sincerely believe the root cause of Autism is genetic damage caused by exposure of one or both of the parents of an Autistic child, or the exposure of one or both of the grandparents or great-grandparents to the same Chromic Acid (hexavalent chromium) emitted in vast quantities from the U.S. Navy metal plating shops at Mare Island and all other U.S. Navy run metal plating shops across this nation for decades. Here is

Here is a direct link to the Scientific article about Autistic Brain Damage posted on the Internet:

Here is a direct link to the Scientific article describing the discovery Autistic Brain Damage is caused by Genetic Damage:

Introduction: If all you do is take the 15 minutes needed to read this Introduction to this large website this is enough. The Navy is always happy to publicize and obtain lots of press coverage whenever one of its new warships is launched. These ships protect us and it is necessary they be the best and the best of anything is always very expensive. We are all aware of the very large money cost to build an aircraft carrier, missile cruiser or destroyer. But what very few people are aware of is the equally huge health cost that is extracted from the workers who build them, the people who live in the vicinity of the shipyards where they are built and maintained, and in the misery that is passed on to unlimited generations of descendants of all of these innocent victims who have absolutely no idea of the incredible price they are paying that is being secretly extracted from their bodies to build and maintain ships.

The one thing that is responsible for all of this human misery now and to come is a single building located in every shipyard. Usually it's a small building and it's purpose is never visible from its exterior. It is the building where chrome metal is plated onto steel ship parts using uniquely toxic chemical baths and electricity. We are all used to chrome bumpers on cars and these cause no fear. But chrome is the hardest metal there is and when a thick coating of it is put onto a steel ship part that undergoes heavy loads and stress that part is provided with a super increased lifetime that is vastly increased over a part that is not heavily chrome plated. It's a process that produces parts for ships that win battles so no one argues with it. The need for chrome plating is obvious to everyone.

When a ship part is chrome plated large amounts of very fine chrome chemical bath droplets mist are discharged out of the plating shop and into the ambient air. This is done to protect the workers inside the shop building. One would suppose that the U.S. Navy being a U.S. Government entity and having access to almost unlimited personnel and money would be the most careful user of the super toxic chrome plating mists and would spend what it takes to capture, control and safely dispose of this poison before it can get to people. But, as this web site more than amply demonstrates this is not done. The U.S. Navy intentionally releases large amounts of this super toxic chemical into the ambient air where shipyard workers will unknowingly breathe it and where wind currents can carry it just about anywhere.

There are two stories about the life robbing and health destructive effects of the super toxic chemicals released from U.S. Navy plating shops that clearly show what I'm talking about. The first comes from 1983 when I began work at the Mare Island Shipyard. I was getting a hair cut at the Sportsman's Barber Shop in Vallejo. While I was waiting my turn the Vallejo City Coroner was getting his hair cut and was talking to the barber. I heard him say, "The one thing I can't figure out is why the average life expectancy of a Mare Island retiree is only 18 months". That got my attention. The second story is more recent. it comes from an episode of the modern TV series, "American Pickers". The two pickers had come to the home of an ex-shipyard worker who had a wonderful collection of things the pickers wanted to buy. They asked the owner why he was selling such choice valuable rare items and he replied, "When I retired from the shipyard I noticed my friends who worked there with me would retire and then they would quickly die so I need to sell this stuff before it's my turn". This also got my attention and it should get your attention. I can think of only one thing that is common to all shipyards that could have this universal and severe life-shortening effect and this is the metal plating shop where chrome is plated onto ship parts.

The worst thing about being poisoned is the victim is always the last to know. What reasonable person could possibly suspect that a U.S. Government organization as large, wealthy and important, and as protective of our National Security as the U.S. Navy would be deliberately and intentionally poisoning and shortening the lives of its workers? Add to this the fact that the U.S. Navy is always bombarding its workers with message to "work safely" and that "their health is the Navy's main concern" or "You have a right to a healthful work place" and other insincere trash its no wonder no one wakes up to the fact that the workers lives have been shortened and their health ruined by the secret poisoning that has been deliberately and secretly done to them. They never wake up to this fact even when their lives are ended shortly after they retire at the age of 55.

The super toxic chrome poison spewed from the U.S. Navy metal plating shops across this nation not only slices off decades of life from the shipyard workers and their families. It passes incredible misery down through the lives of their innocent descendants. In 1983 this chrome chemical called "Chromic Acid" otherwise known as hexavalent chromium or hex-chrome was thought to be merely a nuisance material that ruined the finish on car paint. Today it is known to be the second most powerful cancer causing chemical. Today it is known to cause sinus and lung cancer after a delay period of about 20 years. But there is much more. Any chemical that causes cancer is also a genetic poison. Today it is known that hex-chrome causes human genetic damage serious enough to cause birth defects that can be passed down through subsequent generations. One would suppose that all this bad news about hex chrome would stimulate the U.S. Navy to move to the forefront of those industries stringently controlling the emission of this ultra-super toxic chemical, but this is not so. They proceed as normal killing and maiming people who will be born 100 or more years from now to save money today.

The first reason for all this poisoning is the oldest one in the world: money. It is incredibly expensive to capture the hex chrome mist generated by chrome metal plating. It is incredibly expensive to dispose of the hazardous waste generated when it is properly controlled. It would cost fortunes every day to hire and train the special people needed to establish, maintain and control the minimum necessary equipment and systems necessary to keep us safe. But on top of this there is one over riding main reason the U.S. Navy refuses to do the necessary things.

In the U.S. Navy production is king-emperor-God at the shipyards. The use of U.S. Navy ships is tightly scheduled based upon military necessity. When a ship enters a shipyard for maintenance absolutely nothing must interfere with or delay the scheduled departure date of that ship. And the more modern or the larger (like an aircraft carrier) the ship is the more this golden rule applies. The establishment of a safe and secure control regime for the discharge of hex-chrome into ambient air from a U.S. Navy plating shop would automatically take "stop-work" shipyard wide control out of the hands of admirals in Washington D.C. and hand it over to mere low-level hirelings running the metal plating shop pollution control equipment. This would put ship movement schedule destroying power in the hands of low level environmental hirelings with nothing to loose. This possibility is an absolute absurd worst possible nightmare to the Washington D.C. Admirals and Politicians who control the movement of U.S. Navy ships and it will never happen except for one thing. There is no escaping the thing that is coming.

I am absolutely certain that exposure of individuals to hex-chrome is responsible for the current epidemic of the incredibly horrible human brain birth defect called Autism. I am certain the epidemic scale outbreak of Autism we are suffering under today is the result of the exposure to hex chrome of the grandparents and/or parents of these afflicted children that took place back in the 1960's. Given that the U.S. Navy has continued it's incredibly bad habits with hex-chrome up to today there's no doubt in my mind that this Autism epidemic will continue to grow until at least two generations after the U.S. Navy and other dangerous users of hex-chrome get a grip on the situation and stop emitting this chemical into the environment to the point where the U.S. Population no longer sustains severe genetic damage from being exposed to incredibly small amounts of it.

Every day vast amounts of money are being poured into the search for the cause of Autism. Two years ago it was not known that Autism is caused by genetic damage. Now it is known this is the cause. One month ago it was not known that physical brain damage is Autism. Now it is known. The question being answered now is "what causes this genetic damage". It is certainly now proven to not be the result of childhood vaccinations; but it has to be something historically recent and genetically damaging. Chrome plating did not become popular until the late 1950's. My answer is simple. Any chemical, like Hex-chrome, that causes severe genetic damage to the sinuses which are as close to the Frontal Cortex of the brain as anything can be, can certainly cause genetically caused physical damage to the Frontal Cortex itself and this is what Autism is. In time, I am certain, this will be discovered by science that is working now to find it. When this day comes, and I hope it comes as soon as later today, there will be no escaping the consequences of this fact.

The reason the U.S. Navy has stopped at nothing to keep its decades long poisoning a secret is money. It is the vast, almost infinite and uncountable amounts of money that must be paid to compensate all of its victims from the past, the present and those yet to be born. Just think of it. The U.S. Navy owes more compensation money than all the money printing presses of the world could possibly print in a thousand years. And the sad fact is they just might owe some of it to you or to your grandchildren.

In 1988 the U.S. Navy, through ignorance, accident and circumstance, poisoned me and others with enough hex-chrome to kill us yet we lived. We were poisoned but left uninformed about this and let to go home and vomit into the toilet for weeks while fate determined whether we would live or die. I have lived since then, but not well and not in good health and not with much strength. Fortunately for you I had been properly educated to figure out what had happened once fortune put enough clues in front of me. I am amazed to still be alive. Many of my old shipyard friends are dead. This web site has taken over 20 years of constant searching to find the documents necessary to prove the U.S. Navy to be the poisoner it is. It seems like yesterday I walked into my house, went to the bathroom and started to vomit for two weeks. I think of all my "friends" at the shipyard who knew all about the poising and yet said and did nothing and you should consider this also.

I have lived through many many complex schemes of entrapment at work designed to put me into a position where I would give up my incriminating papers or to destroy my personal reputation so that all that has been written here would be more unbelievable than it actually is. I could write an entire book about all of this but it's not important to the point. The point is the Autism epidemic will not begin to decline until at least two generations have passed from the day the emission of hex-chrome into the environment is reduced to safe levels everywhere. Currently the State of California considers there is no safe level of exposure to Hex-chrome. The adequate control of Hex-chrome will require huge amounts of very intrusive and comprehensive enforcement and the application of technology only slightly less expensive than the cost of injury compensation for the injury already done. But it is necessary because if the current Autism epidemic is allowed to continue it will grow to be more than anything else. It doesn't take too much of a leap of the imagination to come to the conclusion that any unstoppable epidemic of anything has the potential to wreck society. Ask yourself: how many people does it take to care for one autistic child over his or her lifetime? How much does it cost? How many autistic children are necessary to absorb enough of any state or federal budget to wreck it? What about all the misery to come?

I knew a man at work who had an Autistic son and asked him what it was like. He said his life was a nightmare. There is no magic bullet drug for Autism as their is for AIDS.

Forward:

Data available on the Internet and reproduced in this site conclusively demonstrates that the U.S. Navy is the lowest, most despicable and loathsome criminal there is: A deliberate and intentional poisoner and murderer of its employees and innocent civilians who are alive now and those who will be born in the future. If you want to see this data for Mare Island just use this link:

The U.S. Navy is a Poisoner Murderer

This poisoning is has taken place for many decades and is ongoing at an unknown number of sites throughout the USA today in 2016. If you are located next to any U.S. Navy controlled facility of any kind it is in your very best interests to find out if this site has a Metal Electroplating Shop and, if it does, to do everything you can to get your local or state worker safety officials to pay a visit to this Shop and issue a written report to you about the toxic nightmare they find.

This is not a fun site and there is a lot of information in it and so I'm going to answer the question, "why should you care enough to stay here long enough to learn something?". The answer is simple. Wherever there is now or once was a chrome plating shop there is also an elevated cancer rate. Just Google cancer maps and then do a search for chrome plating shops. You will quickly see that they go together. The next question is "why isn't anyone doing anything about this?" The answer is simply chrome plating is absolutely necessary for many important things that we take for granted like airplanes, printing presses, high power engines, food and many other things so there's no getting away from it. The next question is, "why isn't the release of toxic chrome plating chemicals into the environment properly controlled?". The answer is greed. It costs a lot of money to eliminate toxic chrome being emitted into the environment from industrial activities that use and release it. There are not enough regulators and people can be very sneaky where money is concerned. The final question is why is chrome from industrial use so toxic when we actually need some chrome in our bodies to promote good heath? The answer is the hexavalent chrome used in industry is a man made thing that is completely and absolutely un natural. It does not exist in nature like the forms of chrome our bodies need. This hexavalent chrome is foreign and highly toxic to the workings of our bodies and the bodies of everything else that lives like dogs, horses, pigs, fishes, birds, trees, and flowers. There is nothing in our bodies that knows how to handle it, treat it or eliminate it once it gets in. The industrial chrome has an electronic power of six (6) and it acts like a free radical once it gets into the body. This free radical nature allows it to move around and damage the DNA anywhere in the body. It's electronic power of 6 is titanic. This electronic power is far stronger than any other free radical you can possibly inhale or ingest. This titanic electrical damage power makes it like a lightning bolt when it gets to the DNA and it will do permanent damage to the DNA. This is why it is so strong of a cancer causer. But this DNA damage goes even further than personal cancer. It damages the DNA so badly that the DNA damage is inheritable down through your children and grandchildren. This means these genetic defects will go downstream and have the potential to come together and cause severe and untreatable genetic defects years from now. Now you know the answer to the basic questions about why you should care about hexavalent chrome. The purpose of this web site is to show how an extremely large industrial scale user and discharger (U.S. Navy) of this deadly form of chrome is today discharging vast quantities of it into the air and water that you breathe and drink. The U.S. Navy is very clever in its campaign of deception and cover up and so this is why this site is a little complex. But you better believe it.

If you live in an area where there is a shipyard within a half hour driving distance you should look at local cancer maps to see if your home is in a high cancer area. Chances are good it is. You also may want to go to a local library and look in old phone books to find out if there ever were any commercial metal plating shops in your vicinity in the past. Here is why you are being poisoned and made liable to cancer in a nutshell. Chrome is the hardest metal there is. A diamond has a hardness rating of 10 and chrome is 9. There is no metal that even comes close to being as hard as chrome. This hardness means if a metal piece is coated with a thick enough coating of chrome it will have a greatly increased service life and will not fail due to wear unless the service the metal piece is exposed to is extremely severe. This is why the Navy needs hard chrome plating the same way a heroin addict needs a fix. The landing gear of fighter jets that land on aircraft carriers are exposed to the most severe service of anything made by the hand of man. The forces a fighter jet landing gear are exposed to when a jet lands on an aircraft carrier are so great the parts will not last beyond even one landing unless they are thickly coated with chrome. Since the time the aircraft carrier was invented the airplanes that land on them have become heavier, faster and more powerful. These factors have resulted in increasing forces on the aircraft landing gear and other control surfaces. These increasing forces have been compensated for by improvements in the design of this landing gear and also, most importantly, by improvements in the chrome plating applied to these parts. To put it in a nutshell, the Navy has worked with chrome plating, improved it and worked out the procedures to do it so the landing gear have a reasonable service life. The Navy must do its own chrome plating because only the Navy knows how to do it the way it needs to be done. But, even with all this the landing gear don't last very long and even today the Navy is spending a lot of money looking for better alternatives to its traditional chrome plating, but without much success. If you would like to learn all there is to know about the Navy need for chrome plating and its search for alternatives you can view this report:

DOD Report on Chrome Plating and Alternatives

This report is a long download but if you take a good look at it you will know everything you need to know about chrome plating and the Department of Defense (U.S. Navy) and why, from their viewpoint, it's much better to poison your air than to spend the money it takes to control this dangerous chrome six poison.

When a part is hard (thick) chrome plated the chrome layer that is produced is not smooth and shiny like a car bumper. It's rough and bumpy and has to be ground down to make it uniformly smooth and of the proper engineering dimensions so the part will fit into its assembly and will function as designed. While the Navy is very clever about hiding and disguising the amount of chrome plating it does it has not been so clever about the amount of chrome released from all of this grinding. The Navy has reported in official documents submitted to the EPA that in the year 2010 over 122 pounds of chrome metal were discharged into the ambient air. This is a lot of chrome and it all certainly resulted from chrome ground from the surfaces of parts that had been hard chrome plated at the Puget Metal Plating Shop. All of this 122 pounds of chrome resulted in the discharge of toxic chrome plating solution being discharged into the breathing air while it was being plated. If you want to see this section of the report you can use this link:

Typically about 1/3 of the amount of chrome plated is ground off. This means that with 122 pounds of chrome ground off, 366 pounds were plated. This accounts to the chrome plating shop operating full out for at least two shifts per day 50 weeks per year. This is a lot of toxic chrome discharged from air pollution scrubbers left dry and not maintained or monitored.

The problem for you and me is that while the Navy has learned how to chrome plate it has retained the attitude of people from 100 years ago with regard to the highly toxic chrome plating bath mist that is released from the plating shop into the air we breathe. These days modern chrome plating shops that do not have the ability to hide behind a shipyard fence and rooms full of dishonest mouthpieces and who can be sued use engineered controls and devices (scrubbers) to remove the chrome plating solution from the air exhausted from the metal plating shops when chrome is plated. But the Navy has short circuited all this. They have installed scrubbers on their plating shops but do not operate them. The scrubbers are there, and if you are on the shipyards you can see them, but they are for appearance only. A scrubber needs to have water circulated through it but the Navy provides no water flow to its scrubbers. The reason for this is simple and it is money, trouble and guilt. To run water through its scrubbers would cost lots and lots of money. It would also require an organization of workers, engineers and technicians that are currently not there and that would cost money; but even more importantly this organization would produce written records that would demonstrate just how completely and thoroughly the Navy has deliberately poisoned so many people over all these decades and continues to do so even today.

Chrome plating is an inherently inefficient and very dirty process. It is inefficient because the chrome plating bath does not easily or quickly plate chrome. The very thick layer that hard chrome plating produces is not smooth and shiny. It is always rough and must always be made to be too thick so it can be ground down to size using precision grinding wheels. The chrome plating bath uses a lot of electricity to produce a small amount of chrome. This excess electricity produces a lot of bubbling in the chrome plating bath and this bubbling produces a toxic mist of chrome plating bath solution that is released into the air. To protect the plating shop workers air is sucked from the top of the chrome plating tanks and exhausted into the outside air. To protect people outside the shop there are safety devices called "scrubbers". The purpose of these scrubbers is to remove the chrome plating bath droplets from the air exhausted outside the shop. The scrubbers use water to accomplish this removal and as a result the scrubber water quickly becomes contaminated with chrome plating fluid. The big problem with a scrubber is that it produces lots and lots of water contaminated with chrome plating fluid. This fluid is a federally regulated hazardous waste. This means it is very expensive to handle, process, package and dispose of because it is a federal crime to dump it down the drain. It costs at least $50.00 per gallon to dispose of it properly. A plating shop scrubber will produce about nine gallons of this hazardous waste per minute. The Navy reported to the EPA that currently, at Puget Sound, it releases about 122 pounds of chrome per year as a result of grinding of chrome. This means that more than this 122 pounds of chrome had to plated onto things, in one year, in the Puget Sound plating shop. A good guess is that this much plating would produce at least one million gallons of hazardous waste costing about $50.00 per gallon to dispose. On top of this cost is the cost of personnel to handle all of this waste. Then, most importantly there is guilt. If the Navy did all these good things there would be many documents that would show conclusively what should have been done for all these decades and how badly you have been poisoned. This is why you are being poisoned today. The cost to just leave the scrubber to rot without any water being supplied to it and to only maintain it when it becomes an obstacle to plating shop internal operations because it has been left to rot is far less than operating the scrubber properly and handling all the hazardous waste it will generate and dealing with all the accusations and court cases that would result. The amazing cost reduction resulting from the Navy's Chrome Plating Scrubber neglect strategy is disclosed in a report issued in 2006.

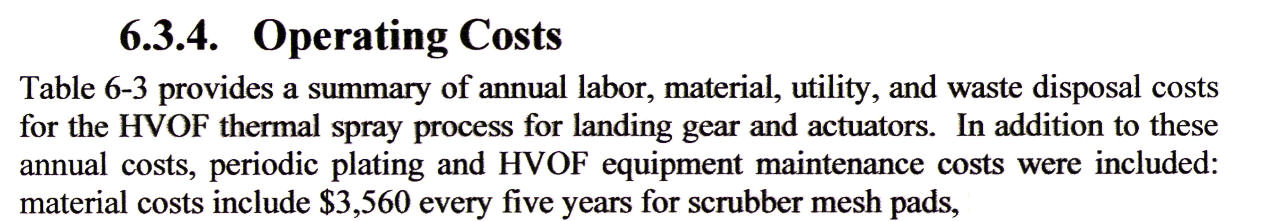

The purpose of this report is to report on the effectiveness of a chrome plating process that uses a flame spray instead of a wet plating bath to apply a thick layer of chrome on parts used in aircraft designed to land on aircraft carriers. But this report contains some very important disclosures about scrubber operation that demonstrate the Navy is even today not providing water flow to its scrubbers. You can view the entire report using this link:

Thermal Spray Chrome Plating Report - 2006

It's about 11 MB and may take some time to load. Here is the section of importance to Chrome Plating Scrubber operation:

It's important to realize that if the U.S. Navy ever bothered to maintain the hex-chrome scrubbers that would have protected the shipyard workers then the costs would certainly have been available. If there is one thing the U.S. Navy keeps a tight track of it's money. If U.S. Navy is spent on anything the data is available. This document is a sure admission by the U.S. Navy that hex-chrome emission control equipment is never and I mean NEVER maintained.

These costs of providing water to the scrubbers were not available. This means the water necessary to operate them was never provided. But one scrubber cost was included that tells the entire tale about how the Navy actually runs its Chrome Plating Scrubbers: What this

What this tells us is the U.S. Navy installs hex-chrome scrubbers, provides them with no water so they do not work, does not maintain them, but instead installs "pads" on them that act as filters. This is to say the entire scrubber is replaced with a single and easily replaceable pad installed on its outlet and that this pad is replaced only once every five years. An entire industrial chrome metal plating shop runs for five solid years on the same thin useless filters? This is a very pure form of insanity that is the result that comes from thinking that relatively small amounts of money are very important and at the same time considering that worker health is of no value at all.

Note that para. G above refers to "Ion Exchange" being associated with scrubber water supply costs. Ion exchange is a method of removing chrome from waste water. Commercial chrome plating facilities that are liable to be sued and who cannot hide behind phony security claims and a shipyard fence must do the right thing. What they do is use ion exchangers (like a water softener) to remove chrome from scrubber water. It's expensive to do this but not as expensive as being fined by the State and Federal EPA or being hauled into court by victims of chrome plating in adjacent neighborhoods. The Navy doesn't have to worry about any of these things and so while it has studied ion exchange it still does not use it. I believe the authors of this report were duped by the Navy so that they would not pry too deeply into the matter of water to the scrubbers. The Navy is invited to prove me wrong about this.

The Navy has rooms of accounts and it knows where every penny goes. When a cost is "not available" this means it does not exist. In this report the Navy says the cost of supplying water to the scrubbers at the Chrome Plating Shop "is not available" but the cost of replacing the final filters on these same scrubbers is available. This means simply the Navy runs its scrubbers everywhere without water and replaces the final filters when they become clogged. The equation is about $100,000,000.00 per year per shipyard vs. $3560.00 every three years per shipyard. Of course, you are absorbing the health cost of the avoided $100 million dollars in savings.

You are poisoned by all the hexavalent chrome being released into the air by the Navy; and the result of this is an elevated ambient cancer rate. The Navy hides behind the fact that the cancers caused by this massive release of chrome into the air will be diffused by statistics so that no particular individual who gets cancer from the shop can file a claim. It's a cruel calculation that has been made and you are its immediate victims. But this released chrome is also a genetic poison that causes inheritable genetic defects. This means that not only you but downstream generations are being poisoned. It would be far better for the Navy to do the right thing. But, right now there are no penalties for their continued refusal to monitor the air coming out of the scrubbers during normal plating shop operations. What the Navy does is it overhauls the scrubbers and operates them properly if state of federal regulators insist on a scrubber test. But once the regulators are gone its back to normal. This site demonstrates how this was done at Mare Island and also how it is being done now at Puget Sound. You can be sure these are not isolated.

How do you know for sure you are being poisoned by the toxic cancer causing Hex-chrome discharged from the Navy shipyard chrome plating shop? The first part of this answer is the Navy is disobeying Navy regulations to keep the discharge of this genetic poison and powerful cancer causing poison a secret. Here's how they are doing it. U.S. Navy Regulations mandate that whenever a safety system is in operation it must be monitored hourly and inspected to make sure it is operating properly by the system operator. Navy Regulations mandate that the safety system must be monitored on a log sheet that the system operator uses to record system pressures, temperatures and flow rates among other things. Navy Regulations mandate these log sheets must be kept indefinitely. The log sheets are an official U.S. Government document and this means it is a federal crime to falsify the data or to refuse to record it. The Navy has simply decided to not monitor the chrome plating scrubber system and to violate Navy Regulations applicable to a vital safety system. The reason for this is to avoid collection of documents that would either force them to spend vast sums of money to operate the scrubber systems properly or to accumulate a pile of documents that will convict the Navy of a federal crime. It's easy to see it's easier an better to just not record the data, not accumulate the log sheets and this is what they are doing. The U.S. Navy has NEVER monitored its chrome plating scrubber systems. It has NEVER collected a single operating log for them. It DOES NOT routinely monitor the performance of the scrubbers. The scrubbers need clean water and lots of it to operate properly. This water absorbs toxic chrome 6 and becomes federally regulated hazardous waste that cannot be poured down the drain. It is extremely expensive to properly handle, package and dispose of the very large quantities of chrome 6 contaminated hazardous waste water a properly operated chrome scrubber will produce. The U.S. Navy has decided to not spend this money by simply letting the scrubbers sit to rot on the plating shop roof without the necessary water flow while you are poisoned. How do you know you are being poisoned? There are two ways. The first is simple and this is to ask if the cancer rate in the area surrounding the shipyard is elevated. The answer to this question is yes at all shipyards. The second is to ask the Navy to show you the scrubber system operating logs that U.S. Navy regulations mandate they must have. EPA safety regulations mandate that YOU have a RIGHT to inspect all records concerning safety equipment that protects YOU so the Navy MUST have these documents and it MUST allow you to inspect them. The answer to this is they will not and cannot produce such documents because they have deliberately not collected them, EVER. The answer to this seems simple to me and this is they know what they are doing and the deadly results. Don't believe me. Just write to the Navy and ask them to send you copies of the chrome plating scrubber system operating logs and monitoring reports and see what you get.

The main message of this site is simple. Imagine if suddenly and magically all the fresh water in the world was to contain a microscopic amount of fertilizer. What would the result of this be? Over time and slowly everything that grows would grow a little faster, bigger and greener and this would continue until someone noticed it. This would probably take a long time. But look at the other side. Suppose all the water was to contain a microscopic amount of a chemical that is a genetic toxin that causes permanent genetic damage resulting in inheritable genetic defects that will slowly accumulate in the plants, fishes, birds, animals and human beings. In the end, this would cause nature itself to crash. This is what hexavalent chrome has been doing to the world since it was invented about 100 years ago. Today hundreds of thousands of tons of this chemical are being used in the USA. Eventually, a great amount of this finds its way into the air and water. Many large cities in the USA have measurable amounts of hexavalent chrome (chromic acid) in their water supplies. You can certainly imagine the long term result of spreading a powerful genetic toxin into the air everything breathes and lives in and into the water everything drinks.

This site is the story, and an excellent example to you, of how much of this genetic poison got released and how it is being released today. People who put profit and productivity first think nothing of poisoning others and, a little bit more each day, everything else that lives. It's also the story about how the damage done already to the health of everyone who was ever within the vicinity of a place where hexavalent chrome is used. It is about how you and them have been robbed of health and life. This Mare Island story is just a typical example. It is a bad example, but it is not, by any means, the worst example. Hexavalent chrome has many many useful and profitable uses. Do some Googling on it and see if it might be in use near you. Then go to that place and have a look. See for yourself that no one is immune.

I had wrongly thought that the Mare Island Chrome VI disaster was unique. But documents recently discovered have demonstrated to me that the U.S. Navy is still covering up the deliberate discharge of tremendously harmful quantities of Chrome VI at other shipyards today in 2012. I am certain that it will not be long before medical science will be able to demonstrate my belief that the tremendously elevated rate of blood cancer or Leukemia and other fatal cancers, in the Puget Sound area is directly related to the U.S. Navy spewing vast quantities of Chrome VI into the air of Puget Sound from the Puget Sound Naval Shipyard Chrome plating shop for decades. If you'd like to read more about this please use this link:

Puget Sound Naval Shipyard Area is being Chrome VI Poisoned Today in 2012

One of the main things this site is meant to demonstrate to you is that the one and only thing you can believe is documents. You cannot believe anything anyone may tell you because, for the most part, they are going to tell you there's nothing to worry about and everything is just fine so you've no need to worry. But, if you ask for documents this is where the fighting will start and the more you insist the bigger the fight will become. If there's nothing to hide, why hide it? Every business that generates hazardous waste must file a document every year with the Federal EPA and this is a public document available to you on the Internet. Go to the EPA web page first to see who in your vicinity, and this means in a 20 mile radius, is discharging hexavalent chrome to the environment. Then, contact them to ask if they are using it and chances are they will say "no". So this can be your starting point. If you are next to a military base believe nothing their well trained and selected spokespersons may say to you. The first place to start with a military or other government installation is the EPA and also your local State EPA. Your state EPA will always have a huge file on any location and you have a right to view it. Just give them a call and make an appointment to visit their office. The point is that any question you may have you must answer as best you can before asking anyone a question. The lies you will be told will tell you the truth if you know the correct answer.

Here is a very recent demonstration of the lengths the Naval Sea Systems Command (NAVSEA), operator of U.S. Navy Shipyards, is willing to go to in order to hide the vast extent its activities are still today in 2012 releasing toxic amounts of hexavalent chrome (chromic acid) into the faces of its workers and communities close to its industrial sites. In 2007 a report was issued whose stated purpose was to evaluate the extent of worker exposure to hexavalent chrome resulting from the conduct of various industrial operations conducted at shipyards, including U.S. Navy shipyards in the USA. This thoroughly dishonest report was constructed to satisfy a need of NAVSEA which I believe is to continue to deny Navy victims of hexavalent chrome poisoning access to their rights and entitlements under Federal Occupational Injury Law. My reading of this report is that it is a bucket of lies whose only possible purpose can to be publish false evidence contrary to the truth about U.S. Navy Chrome VI exposure taking place today. There is specific evidence to demonstrate the data used in this report was "sanitized" at the specific request of the main author of this piece of trash. If you would like to see the real face of the "Force For Good" U.S. Navy please use this link:

Puget Sound Naval Shipyard is being Chrome VI Poisoned Today in 2012

There are three reasons for this web site. The first is that I was poisoned to within an inch of my life by chromic acid during the Plating Shop Chromic Acid Airborne Spill of February 17, 1988. What happened is that I was working on the third floor of the building to the left of the plating shop on the Swing shift. My desk was right next to the window. The whole evening I felt and smelled nothing. The one supervisor on the first floor acted as if everything was normal and told me nothing. It was just a normal work day. Everything was fine until I got home. Then I went right to the bathroom and started vomiting. The vomiting lasted for two weeks during which time I did not go back to work. Then after returning to work, I became overcome by a progressive weakness, lack of energy and ability to do my work. I was afraid of loosing my job because my work was so bad and had no idea of what had happened to me. I got a lucky break and was invited into the Engineers union I.F.P.T.E. Local 25. I asked what the union job was and the answer was to sit in the union office and answer the phone all day. The job would last four years and so I figured by getting the union job I could wait this sickness out figuring that my health problems were some kind of temporary thing. So I got the union job, set a cot up in the union office and tried to recover as best I could. As luck and circumstances would have it I wound up becoming President of the union about the time the Shipyard was to close. One day in 1995 I accidentally found the Chromic Acid Airborne Spill Report from 1988 and immediately knew what had happened to ruin my health. I went to the doctors and they finally told me "It takes a long long time to get over a good poisoning" and that there was nothing that could be done at this late stage to help me. To this day I still live with the effects of this secret poisoning. I did more document searching and found enough to be compelled, by the duty of my office, to prosecute a grievance against the shipyard for unsafe operation of the plating shop because it was clear the plating shop had secretly killed (murdered) many innocent people. I believe that due to the deliberate withholding of evidence and U.S. Navy Perjury, among many other despicable schemes, devices, tricks and frauds, that we lost that grievance. If you are interested in the grievance and want to read it as it was served on the U.S. Navy you can use this link: Grievance.

The second reason for this Site is Immediately prior to the Shipyard closing I held a meeting of the Union membership. I explained to them all the facts that were at hand about how we had all been poisoned for a very long time and the probable long term bad news about chromic acid and its late life effects upon them. It was put to a vote should I continue this matter without limit until true justice is obtained or not. The vote was unanimous that I should continue, regardless of the circumstances, until this matter is resolved in a just and true way. This Site is in obedience to their orders; the orders of my truest friends. It is always a work in progress.

Let me tell everyone who reads this one thing about chromic acid. It is the worst poison there is. It will not kill you, but it will certainly make you wish you were dead and it will do this until the day you die. Chromic acid is not hard to understand. It is easily understood to be a chemical form of nuclear radiation. Nuclear radiation harms people by damaging the DNA permanently leading to cancer and other health problems. Chromic acid does exactly the same thing. Very large amounts of nuclear radiation causes physical injury and permanent disability and very small amounts of chromic acid do exactly the same thing. Nuclear radiation however, does not generally cause genetic mutations that are inheritable. Chromic acid is now known to cause trans generational inheritable genetic damage. Plus, there's one extra thing that chromic acid does: it induces miscarriages in pregnant women. The truth is that the Mare Island Plating Shop was at least as bad as if it was a melting down nuclear reactor of the same size and was probably much worse.

Here's the bottom line about how much Chromic Acid was blasted into the breathing air by the metal plating shop:

1. When the U.S. Navy Perjury is corrected so that U.S. Navy calculations, that do not account for or use all available data, are corrected to merely eliminate the perjury, the results of the normal chrome scrubber operating conditions are that the chrome plating air scrubbers on the roof of the metal plating shop blasted out extremely large volumes of air contaminated with Hexavalent Chromium at the following levels:

1. Hard Chrome Plating Scrubber: 2.2 Times the 1988 OSHA Permissible Exposure Level

2. Decorative Chrome Plating Scrubber: 9.8 Times the 1988 OSHA PEL

These are massive exposures that will cause injury and death.

2. When complete calculations using all available data is used to Calculate the Amount of Chromic Acid emitted from the scrubbers the normal conditions result is:

1. Hard Chrome Plating Scrubber: 5.2 Times the 1988 OSHA PEL

2. Decorative Chrome Plating Scrubber: 19.7 Times the 1988 OSHA PEL

These are extraordinarily massive exposures that will cause injury, death and immediate adverse permanent health effects.

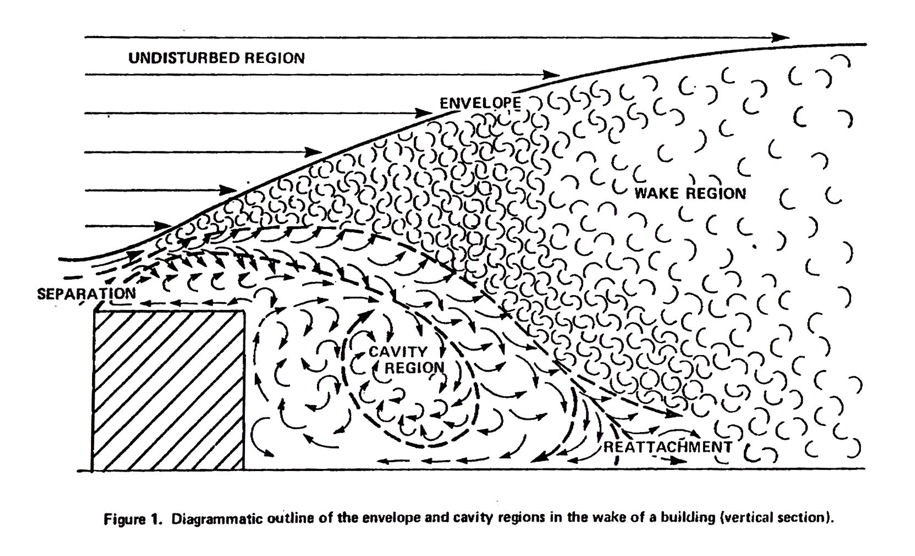

The amount of air blasted from the plating shop containing chromic acid at these levels of exposure was extraordinarily large. The Hard Chrome plating scrubber discharged 17,000 Cubic feet per minute and the Decorative Chrome plating scrubber discharged 10,800 Cubic feet per minute of contaminated poisonous air simultaneously each minute of every day of the year for decades. This is such a large volume of air it could not simply "dissipate" and become diluted by ambient air. It filled up the area surrounding the plating shop, displacing the ambient air, and it was not for a considerable distance from the plating shop before the concentration of chromic acid would begin to decline due to dilution by ambient air. You would have had to be miles from the plating shop before the chromic acid exposure level would have been reduced by dilution to the current "no harm" exposure level of 0.0001 micrograms per cubic meter of air. But even with a considerable distance wind currents would have brought high concentration plumes to your vicinity from time to time.

3. If you want to see the U.S. Navy Perjury document and the corrected U.S. Navy calculations use this link: PERJURY

4. If you want to see the page that uses complete data and U.S. Navy methods to calculate chromic acid releases use this link: CALCULATIONS

This Web Site is about the nuts and bolts of how the U.S. Navy allowed, covered up and still refuses to admit the massive poisoning of uncounted thousands of innocent victims with this horrible chemical for decades. Chromic acid is used mostly for chromium plating and tanning leather but it is also used in preservative paints used on military aircraft, for precision cleaning purposes and for the making of pigments. When breathed it kills lung tissue permanently and causes a kind of fibrosis similar to emphysema. It also causes asthma and many other diseases. It is the second most powerful lung and sinus cancer causing agent known to man. It is odorless, colorless and tasteless and it is a local anesthetic. All these factors explain why it was possible for the U.S. Navy to keep the fact that many thousands of innocent victims were constantly exposed to extremely harmful levels of this chemical for many decades and these cowards continue to refuse to admit it up to the present time.

Chromic Acid is used in metal plating shops everywhere throughout the world. It is used to plate a thin layer of chrome for decorative purposes (decorative plating), a very thick layer of chrome for wear proofing heavy duty equipment (hard plating), and it is used to anodize aluminum. During these processes large quantities of electricity are passed through large volume baths of chromic acid dissolved in water. Also, large quantities of compressed air are introduced into these baths to keep them well mixed. The passage of electricity (Amperage) and the passage of compressed air bubbles through these baths causes the generation of a highly toxic chromic acid mist. To protect the workers in the shop this mist is sucked up from the surface of the tanks by air vents and powerful large fans. This air is passed through an air cleaning device called a Scrubber before it is exhausted to the outside air.

The purpose of the air cleaning scrubber is to protect people who are outside the shop and who don't know the great danger posed to their health by the chromic acid mists being generated inside the shop that are then discharged from the shop. For all the time the Mare Island Naval Shipyard Metal Plating Shop was in operation for over 67 years, there were either no scrubbers installed or when they were installed they were completely ineffective at capturing toxic mists of chromic acid because they were not monitored to ensure they were operating properly, the were not maintained, the were not provided with cleaning water and the people who were tasked to operate them knew absolutely nothing about how to operate them. But this is by no means all of the crime. In 1987 and 1988, when the Bay Area Air Quality Management District put the Mare Island Plating shop permits to operate chrome plating tanks in jeopardy and mandated the chromic acid removing scrubbers be tested, Mare Island engaged in very clever schemes of massive cheating in dishonest attempts, which were finally successful, to keep their permits to operate the chrome plating tanks and discharge polluted air to the air outside the shop. This is a link to the CHEATING page that discusses this cheating. It is currently a work in progress. You are welcome to review it while it is being prepared:

U.S. NAVY CHROME SCRUBBER TEST CHEATING

Because the extremely unique toxic nature of chromic acid this willful, deliberate, reckless negligence by the U.S. Navy has doubtlessly been responsible for many thousands of deaths from cancer and disease, crippling due to ill health, birth defects, lung disease, heart disease and many other disabling conditions and diseases.